NEW Launch! DESS® Screws for Superstructures

The field of implant dentistry is continuously advancing with the introduction of innovative techniques designed to improve prosthetic restorations and consequently enhance the quality of life for patients.

Recently, a trend involving Direct on Multiunit techniques is emerging within the area of prosthetic restorations. This development is prompting dental professionals to manufacture prosthetics without a Ti-Base in Multiunit cases, marking a significant shift in traditional practices.

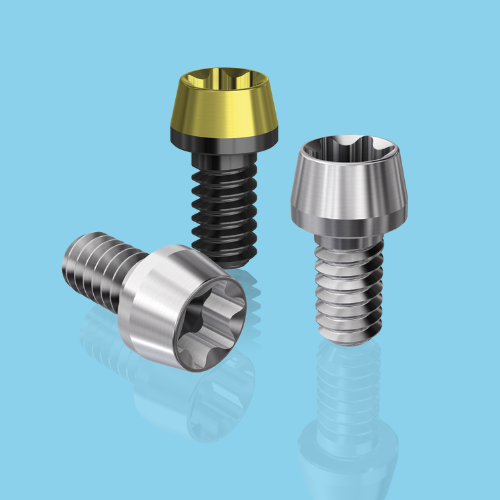

DESS® Flat Seat Screw vs Rosen Screw vs Powerball Screw vs Vortex Screw

As a consequence, many manufacturing companies have developed their own solutions for Direct on MUA cases. Some of these solutions are the “Rosen Screw”, Powerball screw, WTI Screw and Vortex Screw. They all have one thing in common: conical shaped screw-based solution.

Limitations of Conical Screws: Rosen Screw, Powerball Screw, Vortex Screw

All these solutions are based on the principle that the conical shape prevents the screw from loosening. However, mechanically, the conical screw is designed to align itself within the connection geometry of the Multiunit Abutment (MUA). As a prosthesis is connected to multiple implants, it is improbable that all the connection geometries will perfectly center over their respective MUAs. Therefore, this misalignment can potentially lead to mechanical instability and compromise the long-term success of the implant-supported prosthesis.

This effect will put pressure on either the screw or the prosthesis depending on which one of these two things are stronger.

- If the screw is the weaker component of the two, a bending force will be applied to the screw, and this may cause screw fractures.

- If the prosthesis is the weaker component of the two, the forces may cause the prosthesis to break more easily.

Additionally, and as proven in testing by our Engineering Department, a conical screw brings the following consequences:

- Preload reduction between zirconia and the MUA.

- Contact surface is highly dependent on the inaccuracies of the milling machine.

- Unpredictable final screw seating height.

- Collision problems on early screw loosening.

- Possible offset between zirconia axis & MUA.

- Screw stuck inside the seat.

Taking all the above tested facts into account, DESS® has developed an alternative solution for those direct on Multi-Unit cases: DESS® FLAT SEAT Screw.

DESS® Solution for Direct on MUA restorations is based on a Flat Seat Screw Design, which will bring the following features:

- Higher preload force between full arch and MUA.

- Allows divergences in the milling screw holes.

- Safe and predictable surface contact area despite deviations in manufacturing.

- Flat seat provides better control of the screw positioning height & turns when tightened.

- Flat seat allows room to play, better absorption of the milling divergences and self-centering of the screw towards the axis of the MUA.

Our tests demonstrate that, when applying the same force, the DESS® FLAT SCREW gets better preload, since it distributes the forces evenly around the seating surface.

Amongst the previous information, we can conclude that the new Multi-Unit Abutment Screw offers much more benefits for the final prosthesis. The increased seat thickness, which offers more resistance, provides a more stable and durable restoration.

The final restoration is, therefore, less susceptible to breakages, even with softer material such as temporary prosthesis.

Last but not least, the new DESS® Screw, has a Torx socket design, which will allow in combination with the DESS® libraries, to perform angle screw channels up to 25°, perfect solution to achieve the best superstructure strength and correct the screw channels to get the best aesthetic result.